Product Description:

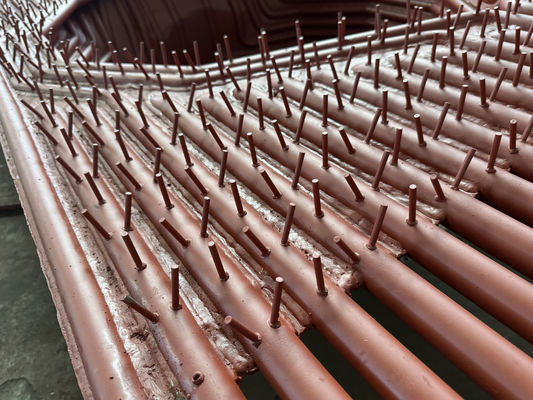

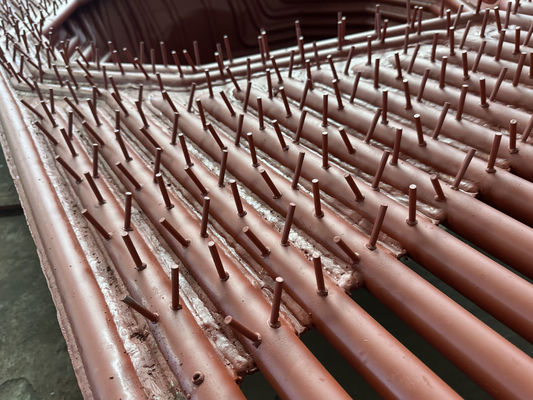

With dimensions of 38.1*3.2, the Boiler Membrane Wall is crafted to precise specifications to fit various boiler systems seamlessly. The use of Submerged Arc Welding technique ensures strong and durable welds, providing structural integrity to the entire system.

The Boiler Membrane Wall serves as a crucial component in the boiler tubular membrane wall system, contributing to the containment and efficient transfer of heat within the furnace. Its flexibility allows it to adapt to different boiler configurations, making it a versatile choice for various industrial applications.

When it comes to enhancing boiler performance and durability, the Boiler Membrane Wall is a top choice due to its superior construction and design. The new condition of the product guarantees that it is free from any defects or wear, providing peace of mind to operators and maintenance personnel.

Investing in the Boiler Membrane Wall means investing in the long-term efficiency and reliability of your boiler system. Its high flexibility makes it easy to install and maintain, while its robust construction ensures that it can withstand the rigors of continuous operation.

Whether you are looking to upgrade an existing furnace membrane wall system or are in need of a reliable component for a new boiler installation, the Boiler Membrane Wall is an ideal choice. Its precision dimensions and quality welding technique make it a standout product in the market.

Experience the benefits of a high-quality Boiler Membrane Wall and elevate the performance of your boiler system today. Trust in the expertise of a specialized manufacturer to deliver a product that meets and exceeds your expectations for efficiency, reliability, and longevity.

Features:

-

Product Name: Boiler Membrane Wall

-

Model: Boiler Part

-

Flexibility: High

-

Manufacturer: Specialized Boiler Membrane Wall Manufacturer

-

Pressure: Low/High Pressure

-

Processing Technology: Welding

Technical Parameters:

|

Welding Way

|

Submerged Arc Welding

|

|

Model

|

Boiler Part

|

|

Surface Treatment

|

Painting

|

|

Installation Method

|

Welding

|

|

Dimension Of Tube

|

38.1*3.2

|

|

Temperature Range

|

Up To 600°C

|

|

Flexibility

|

High

|

|

Welding Technique

|

Submerged Arc Welding

|

|

Pressure

|

Low/High Pressure

|

|

Tube Material

|

SA 210 A1

|

Applications:

The Boiler Membrane Wall product is a critical component in various industrial boiler systems, offering exceptional performance and reliability. With its advanced Submerged Arc Welding technique, this product ensures superior weld quality and durability, making it suitable for high-pressure and high-temperature applications.

One of the key application occasions for the Membrane Wall Boiler Panel is in coal, gas, or oil-fired boilers where water heat is utilized for steam generation. The sealed design of the Boiler Sealed Membrane Wall helps in efficient heat transfer, ensuring optimal boiler efficiency and energy savings.

Constructed from high-quality Carbon Steel or Stainless Steel materials, the Boiler Tubular Membrane Wall provides excellent corrosion resistance and longevity, making it ideal for harsh industrial environments. Its flexibility allows for easy installation and maintenance, reducing downtime and operational costs.

Whether used in power plants, refineries, or other industrial facilities, the Membrane Wall Boiler Panel plays a crucial role in ensuring safe and efficient boiler operation. Its high flexibility enables customization to fit different boiler models, making it a versatile choice for various boiler systems.

In summary, the Boiler Membrane Wall product is a reliable and high-performance solution for industrial boilers, offering exceptional durability, efficiency, and flexibility. With its advanced welding technique, compatibility with different fuels, and quality materials, this product is a top choice for achieving optimal boiler performance and longevity.

Customization:

Product Customization Services for the Boiler Membrane Wall product:

Welding Way: Submerged Arc Welding

Model: Boiler Part

Tube Material: SA 210 A1

Condition: New

Welding Technique: Submerged Arc Welding

Keywords: Furnace Membrane Wall System, Boiler Membrane Wall, Boiler Tubular Membrane Wall

Support and Services:

The Product Technical Support and Services for the Boiler Membrane Wall product include:

- Installation guidance and support to ensure proper setup and functioning of the membrane wall system.

- Troubleshooting assistance for identifying and resolving any issues with the membrane wall.

- Regular maintenance services to prolong the lifespan and efficiency of the membrane wall.

- Training programs for operators and maintenance personnel on how to operate and care for the membrane wall effectively.

Packing and Shipping:

Product Name: Boiler Membrane Wall

Description: High-quality membrane wall for boilers

Package Contents:

- 1 Boiler Membrane Wall panel

- Installation instructions

Shipping Information:

- Shipping Method: Standard

- Estimated Delivery Time: 5-7 business days

- Shipping Cost: Calculated at checkout

FAQ:

Q: What is a Boiler Membrane Wall?

A: A Boiler Membrane Wall is a type of water-cooled panel used in boiler construction to increase efficiency and durability.

Q: How does a Boiler Membrane Wall work?

A: The Boiler Membrane Wall acts as a barrier between the combustion gases and the water in the boiler, allowing for heat transfer while protecting the boiler's structure.

Q: What are the advantages of using a Boiler Membrane Wall?

A: Some advantages of using a Boiler Membrane Wall include improved heat transfer efficiency, reduced maintenance costs, and increased boiler lifespan.

Q: How durable is a Boiler Membrane Wall?

A: Boiler Membrane Walls are designed to be highly durable, with the ability to withstand high temperatures and pressures, making them ideal for industrial boiler applications.

Q: Can a Boiler Membrane Wall be customized for specific boiler designs?

A: Yes, Boiler Membrane Walls can be customized to fit specific boiler designs and requirements, ensuring optimal performance and compatibility.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!